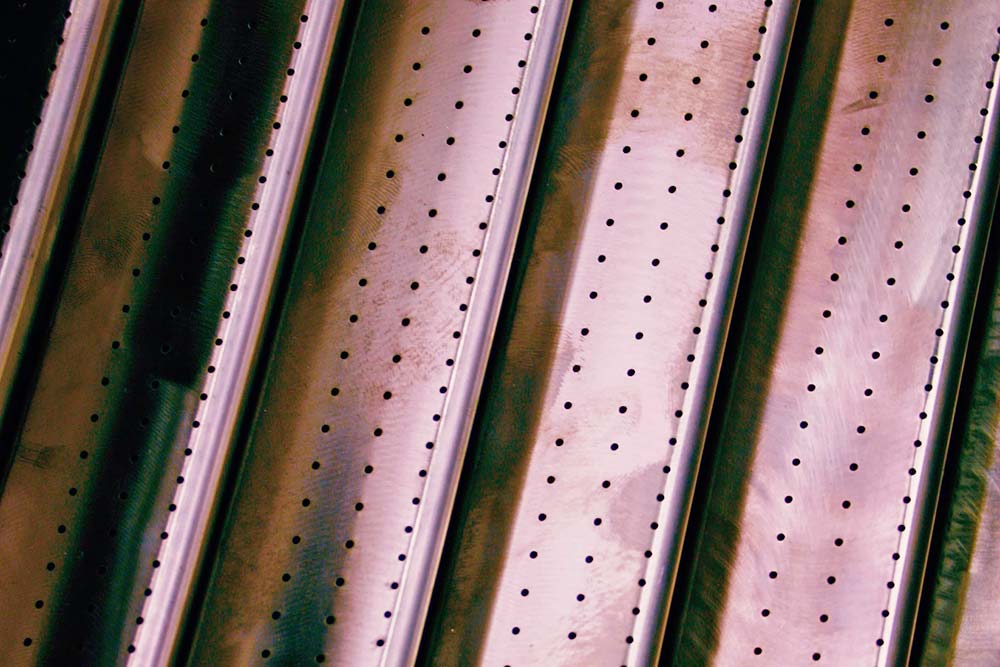

Roll Forming

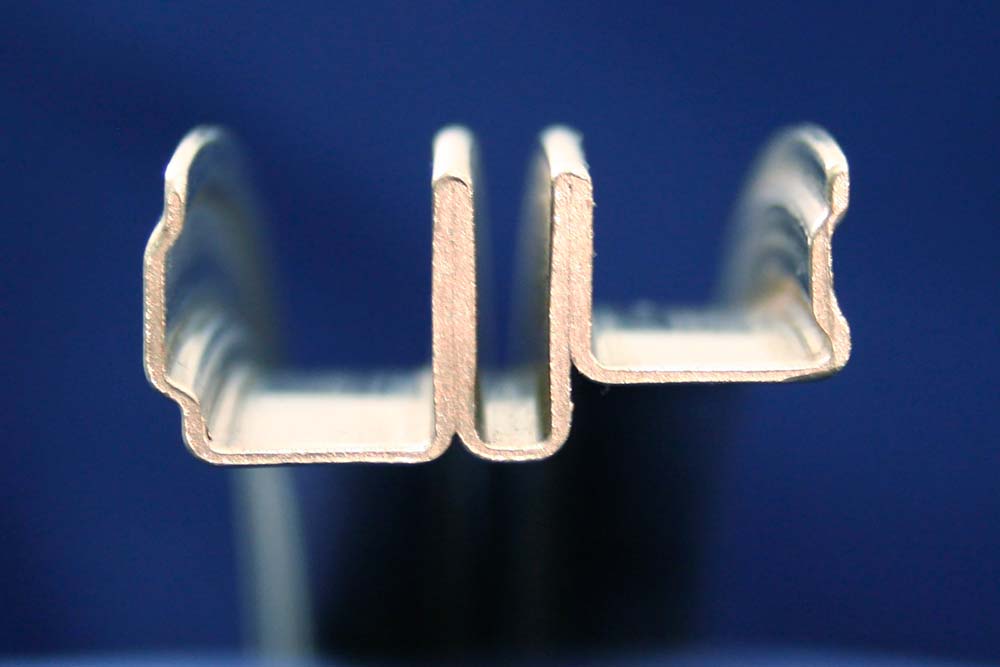

Complex one-piece shapes in a single operation

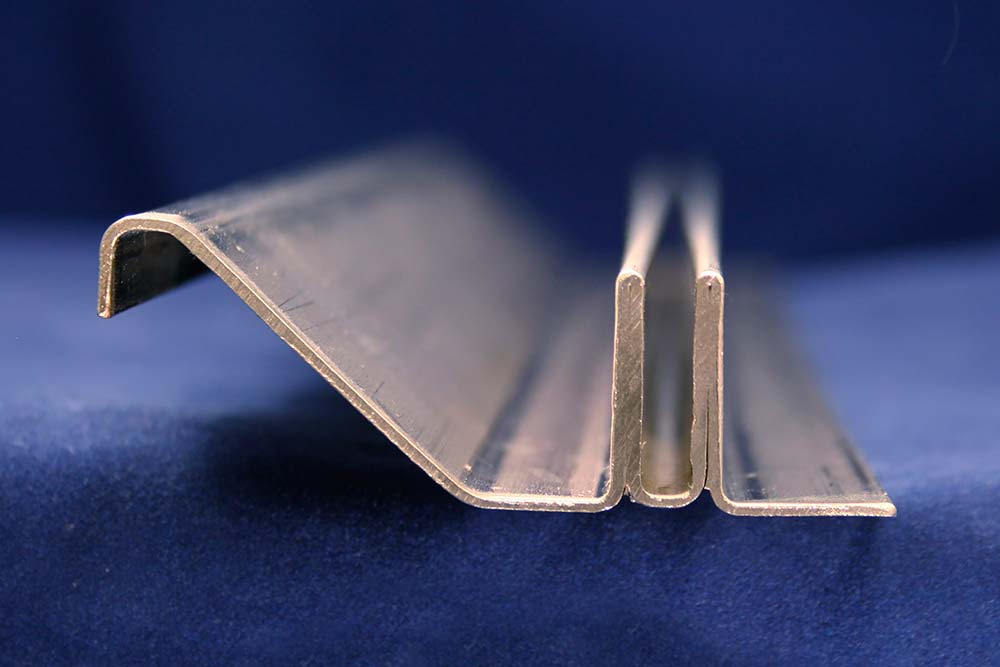

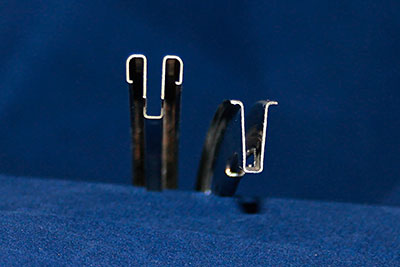

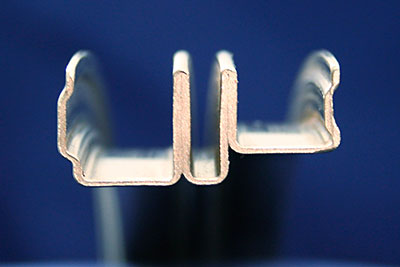

Unique among all metal forming methods, the roll forming procedure allows a flat strip of metal to be progressively formed into a complex one-piece shape in a single operation. This process assures a smooth flow of material from the first to the last phase and allows maximum dimensional control to the finished part. Roll forming presents engineers with the utmost in design flexibility, freeing them from conventional shapes. The process also frequently eliminates costly secondary sub assembly and fabrication operations.

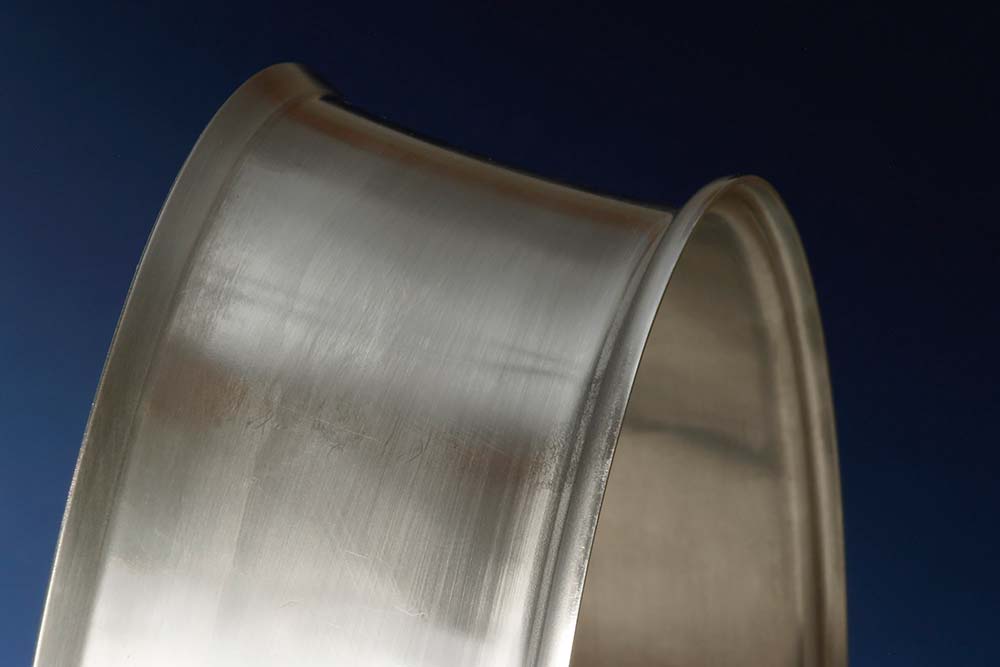

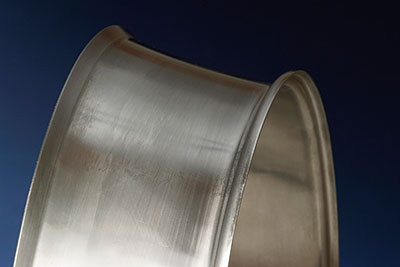

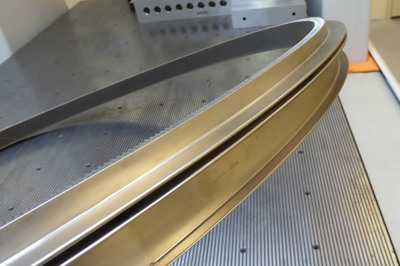

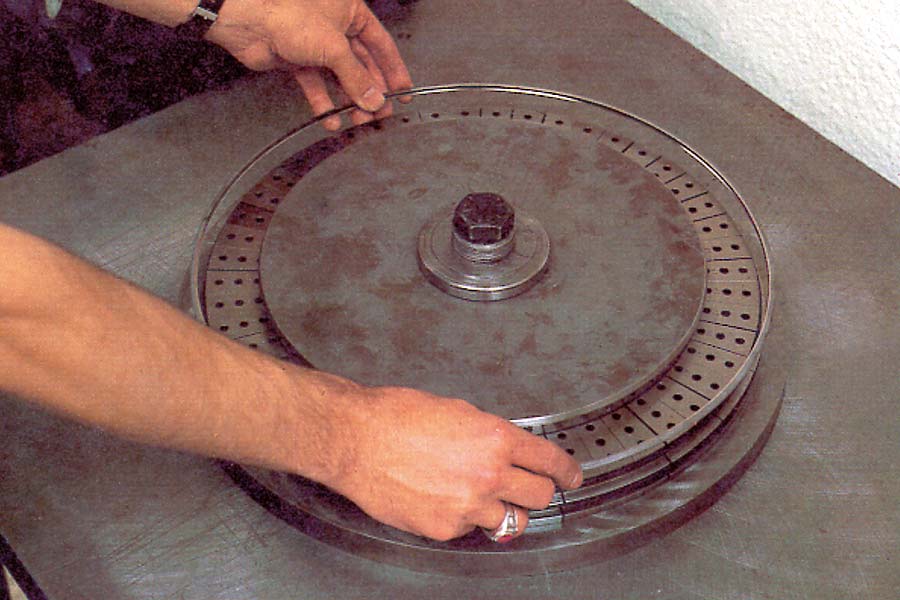

Cold Sizing

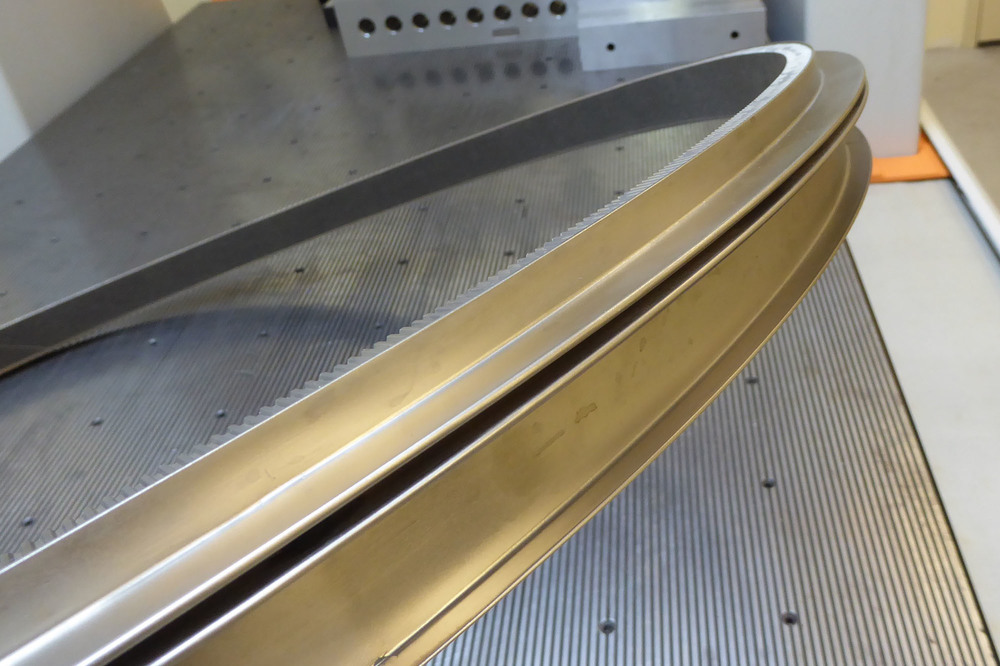

Very fine toleranced rings

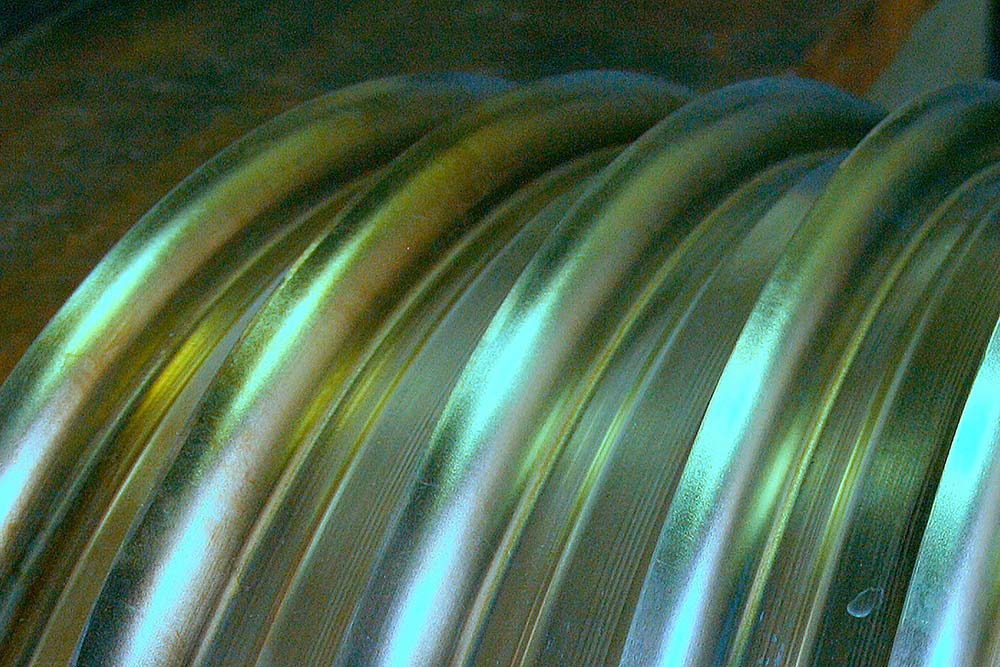

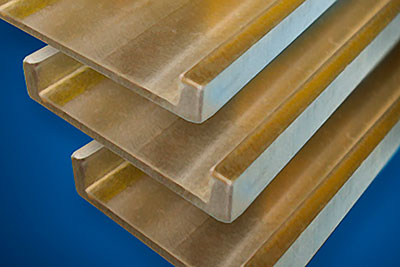

For rings demanding extremely close tolerances, Dynamic can “Cold Size” them to their finished diameter. This process starts with a 360-degree welded ring formed from a roll formed section or an extrusion. The ring is placed on a sizing die that has been designed with expanding pie-like sections. The ring is then gently expanded to the exact diameter.

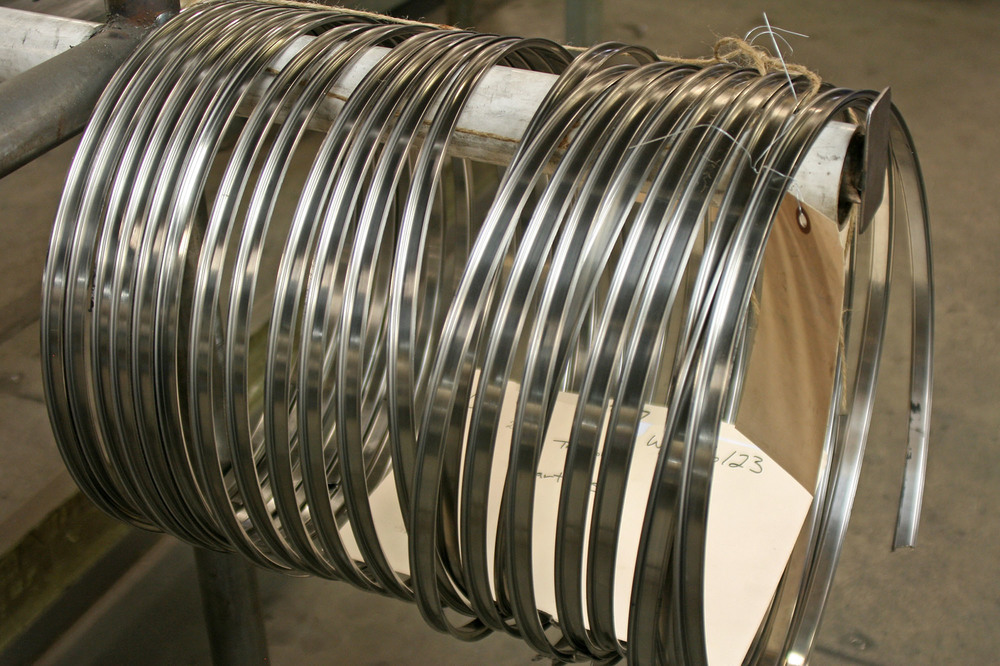

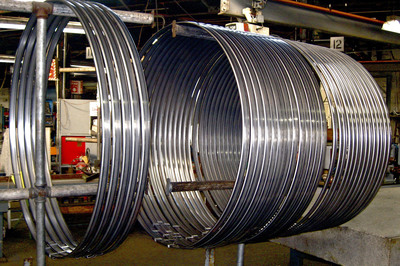

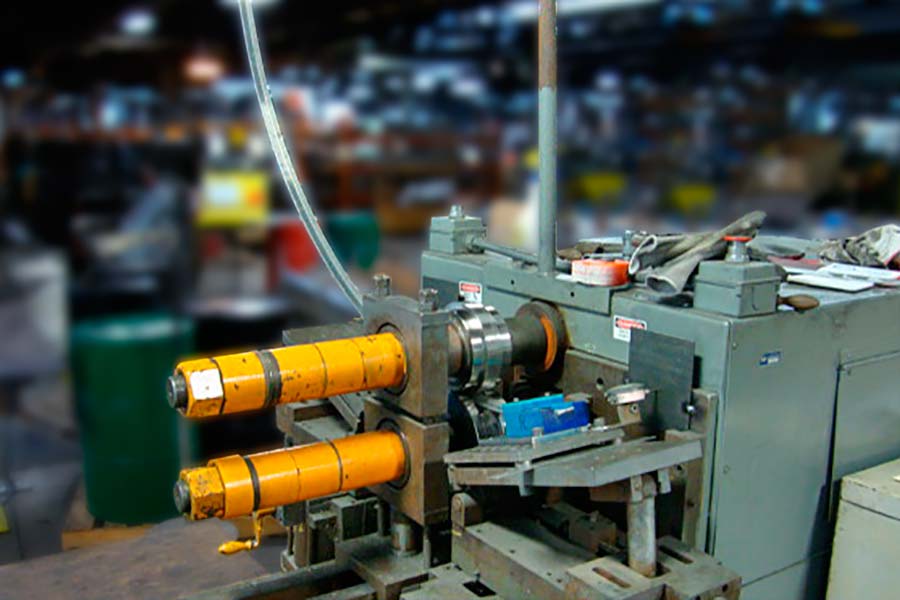

Ring Rolling

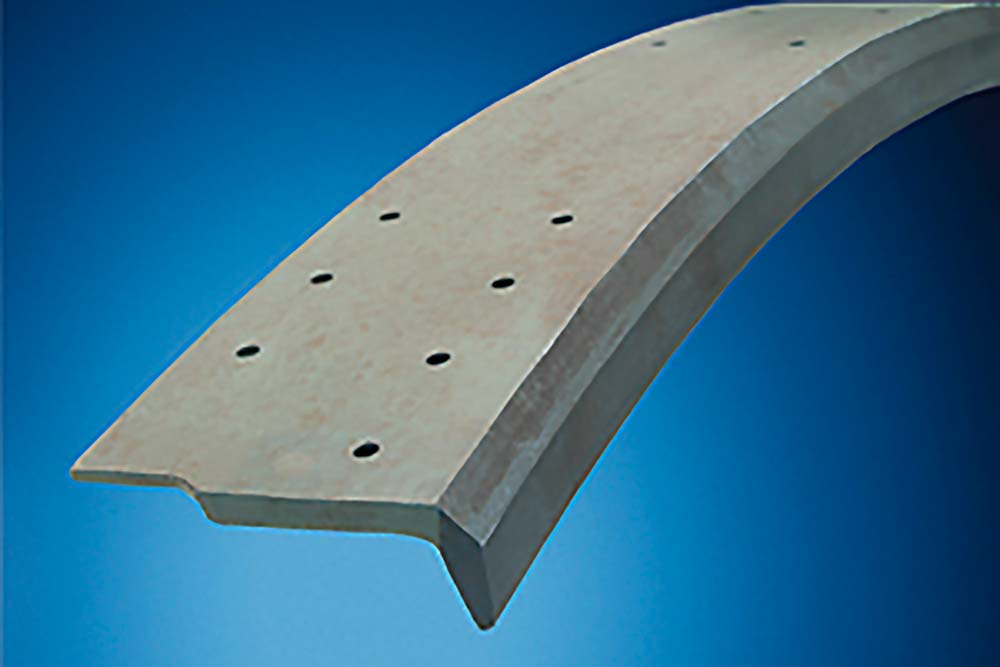

An economical alternative to spinning, hydroforming, and machining

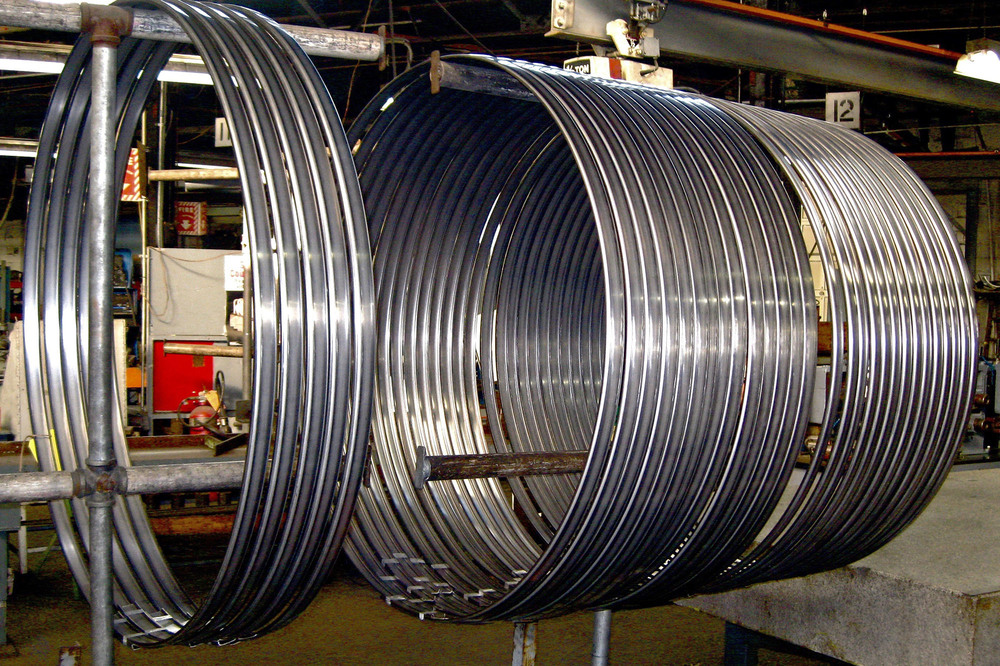

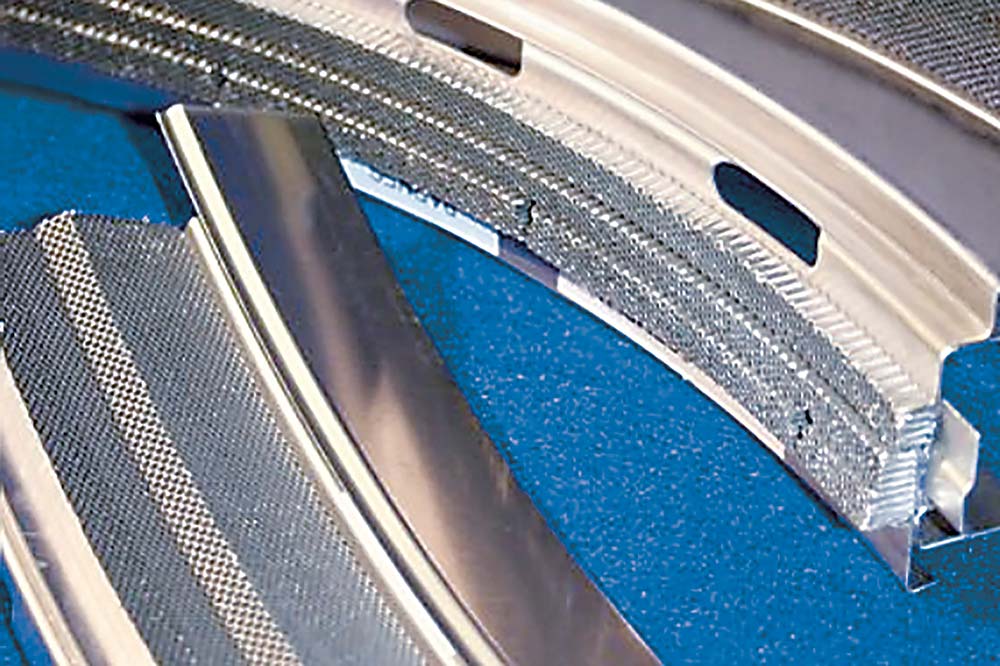

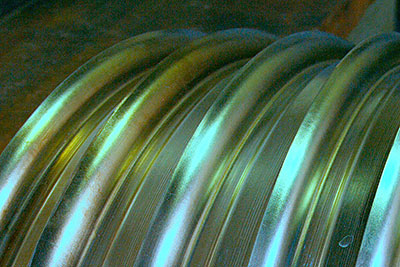

Dynamic Metals has developed a unique ring forming process referred to as “Ring Rolling.” Starting with a straight length that has been roll formed or extruded to its desired profile, the piece is passed through a set of roller dies several times and gently formed into a curved shape. Each pass increases the curvature by a small amount until the desired radius has been achieved.

Many “ring rolled” parts are supplied as segments; however, this process also produces complete 360-degree rings whose ends may be welded together. This process is an economic alternative to spinning, hydroforming, or machining, and provides significant savings to the customers.

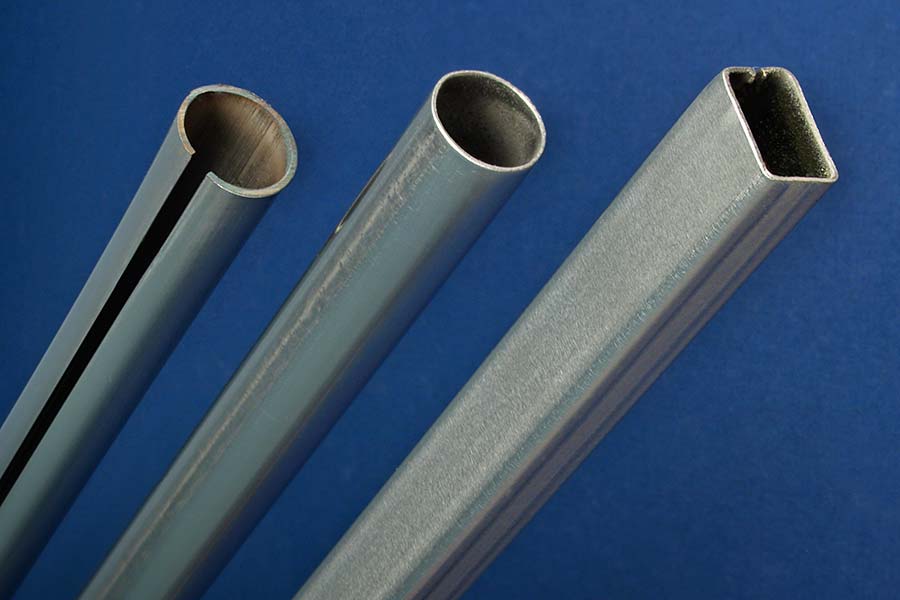

Re-rolling

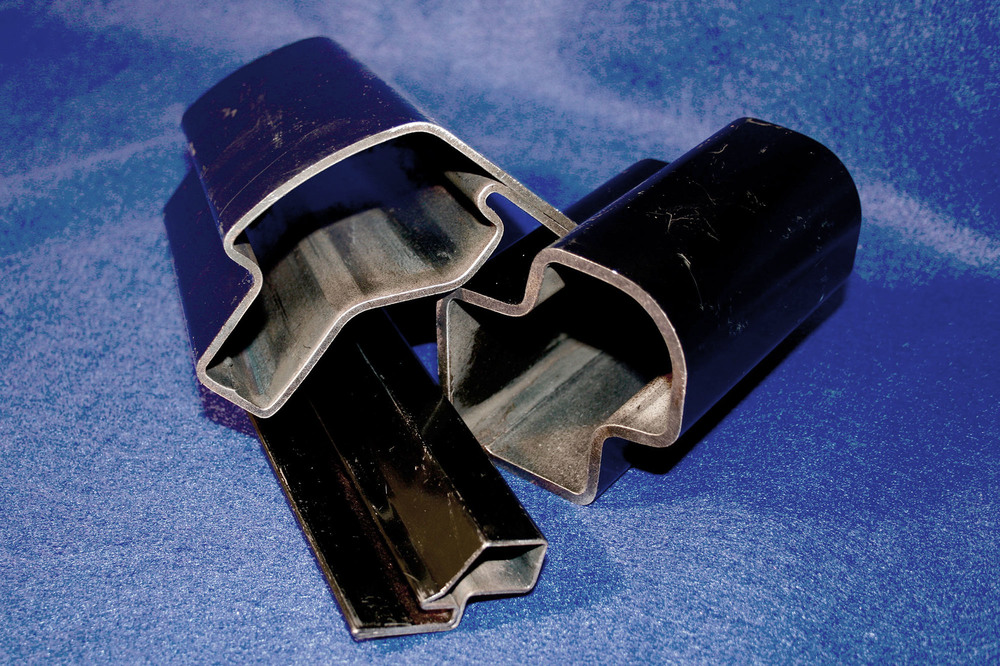

An efficient way to produce rectangular configurations

Dynamic is also capable of re-rolling straight round welded tubes into various shapes. Special roll form tooling is designed and built to match the final tube profile. Round welded tubes are fed through the roll former to impart the final shape. Most commonly, round tubes are re-rolled into rectangular configurations for various applications, including jet engine manifold tubing.

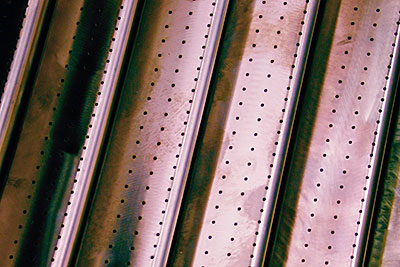

Welded & Bent Tubing

Exact tolerances

Our specialty welded tubing is produced to the same exacting tolerances as our custom products. Available features include:

- Nickel and cobalt alloys for corrosion and heat resistant applications

- Precipitation hardening of stainless grades for high strength mechanical applications

- Specially-designed shaped tubing in all grades rolled to provide a net shape

- Process applicable to vane production

- All orders are custom made to specific requirements

- Available in bent or straight shapes

- Nadcap approved for fusion welding