Laser Technologies

Multi-axis machinery producing ultra-precise results

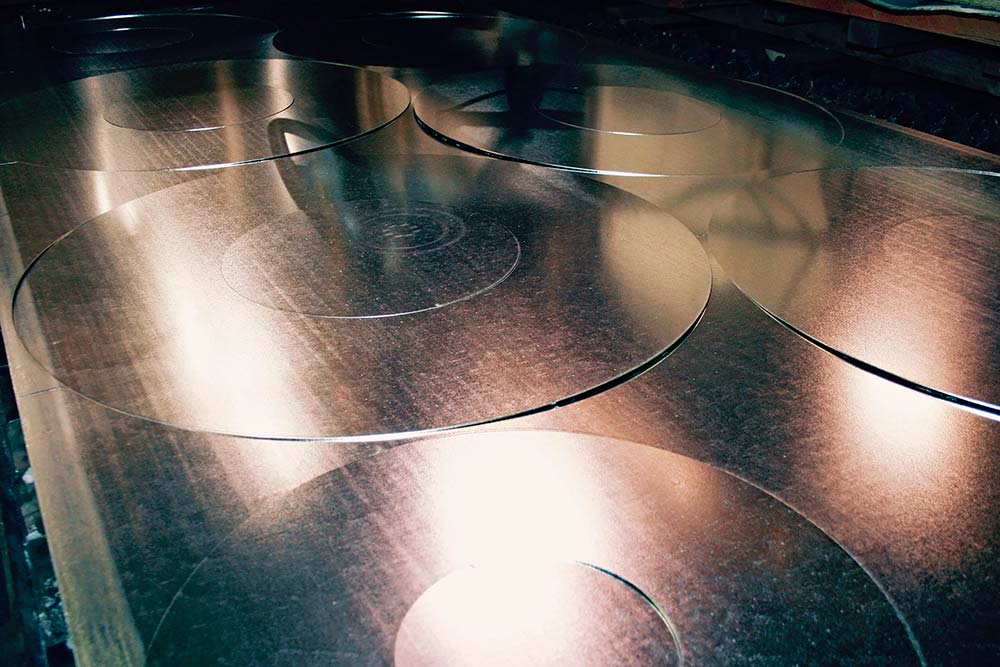

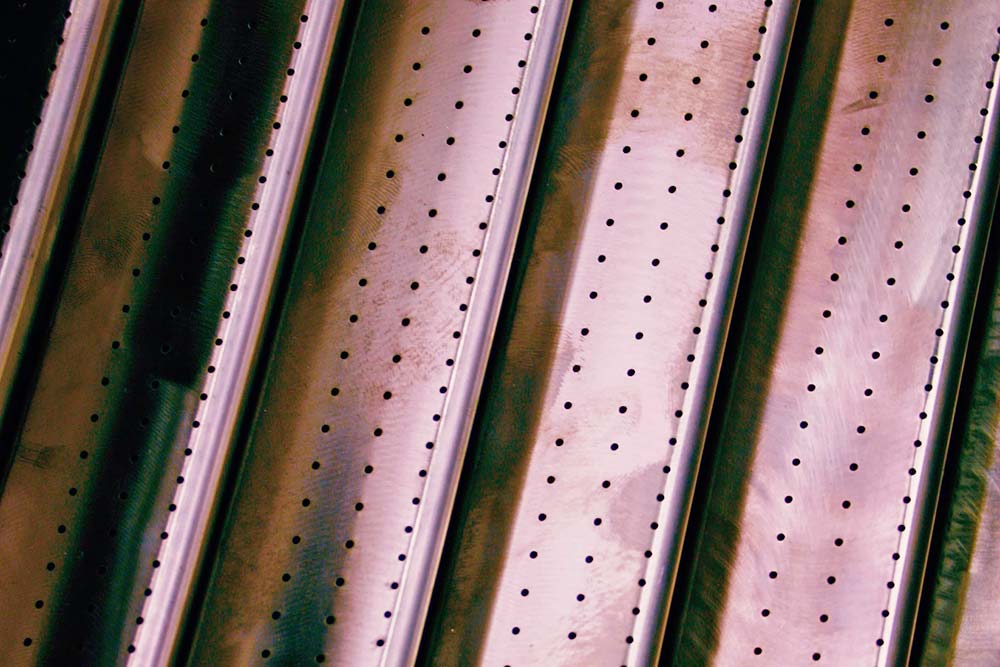

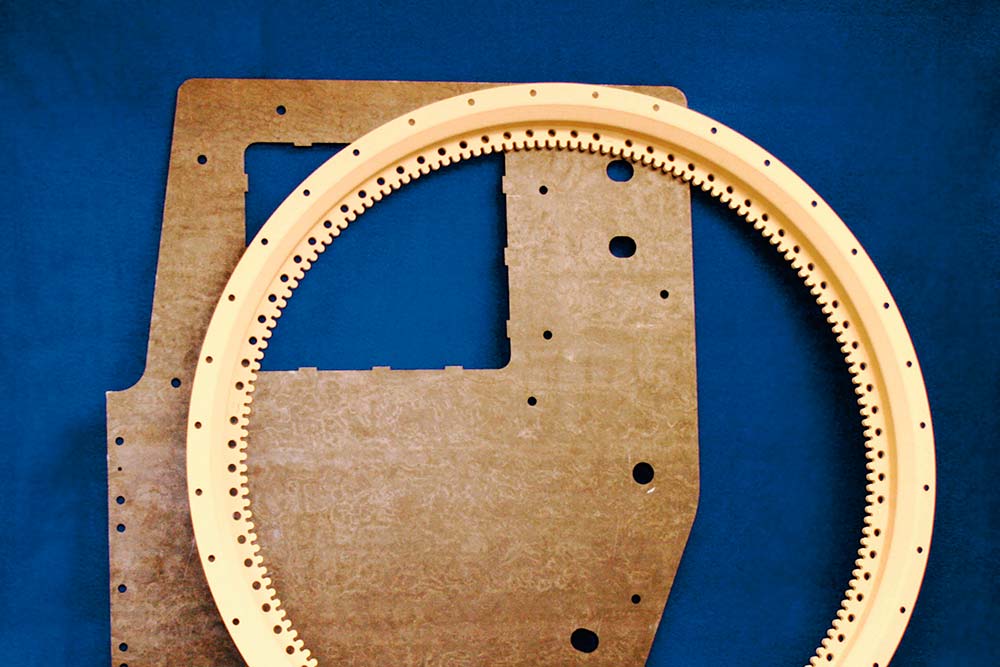

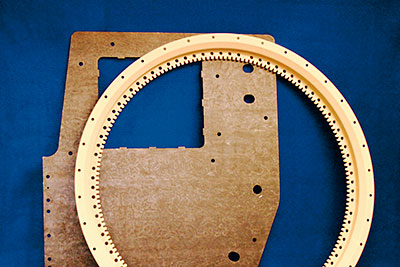

Beyond more traditional forming and stamping methods, Dynamic employs a diverse portfolio of laser technologies including multi-axis machines for trimming and piercing top-assemblies, flat pattern cutters to support raw material input and high-production laser welding cells to meet the fast paced automotive industry. We’re perpetually innovating and will continue to incorporate the latest technologies and non-conventional machining to provide the best value to our customers.

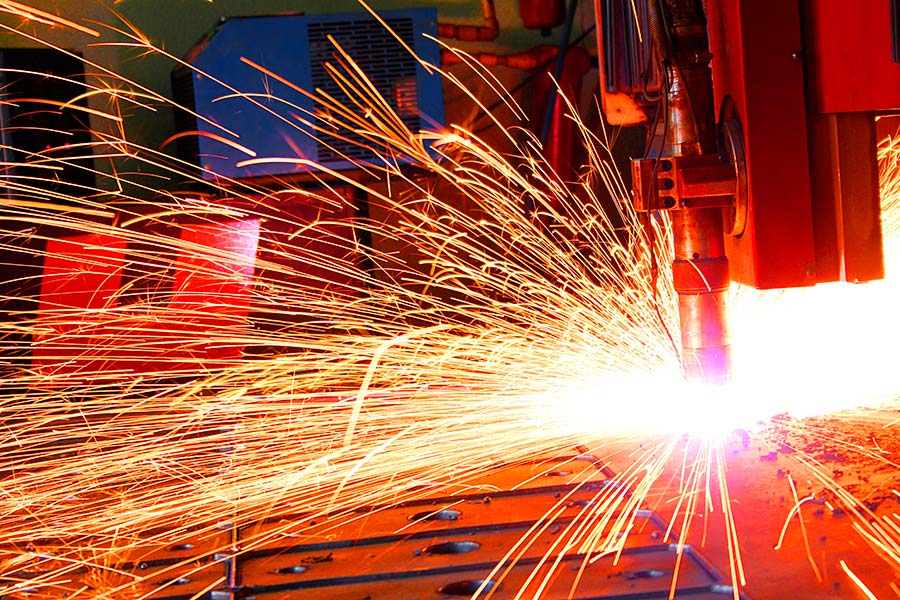

Laser welding

Nadcap certified, Dynamic is an approved source for a variety of fusion welding applications including OEM approvals for GE Aviation and Rolls-Royce. In support of our military fabrication business segment, our welders are certified to AWS D1.1, 1.2 and 1.3, and we are approved to Tardec 12479550.

Laser and robotic welding have been integrated into our high-production automotive division. Resistance welding is also incorporated into our blend of joining materials at our three Midwest locations.