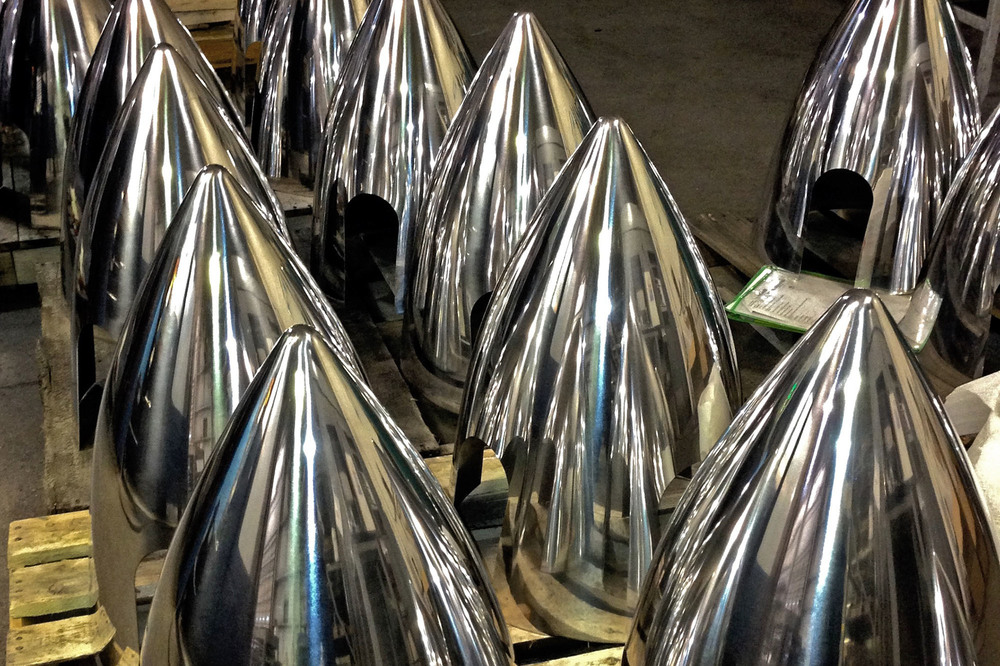

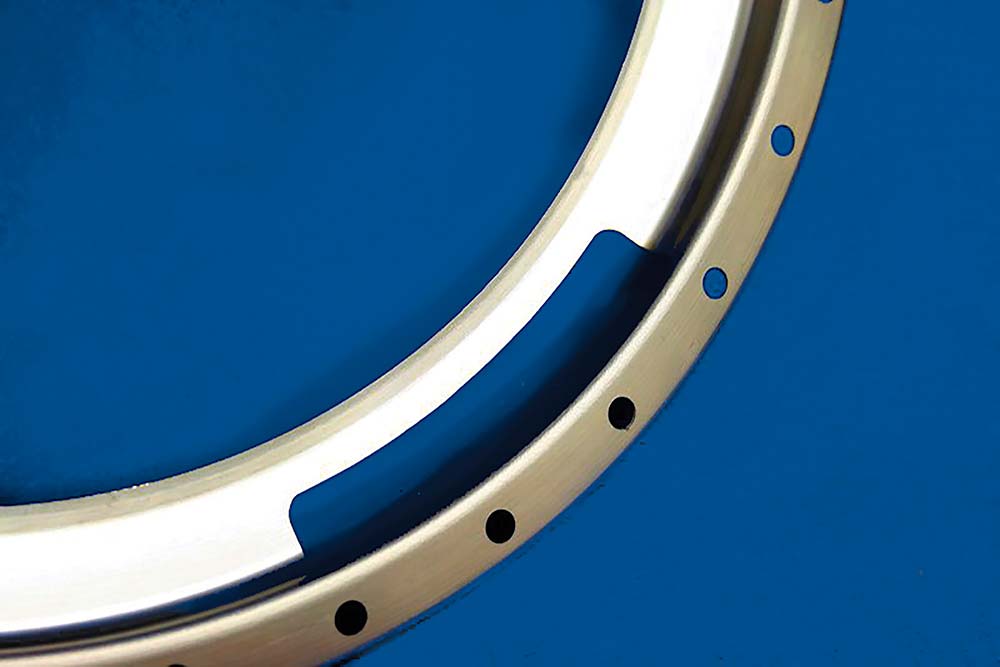

Spinning

A rare blend of art and science

Our heritage dates back to the early 1950’s and at the core is our ability to shape and spin metal and we have made the commitment to expand and keep pace with the latest technology ever since. As markets changed, new demands also helped us develop new applications and innovations.

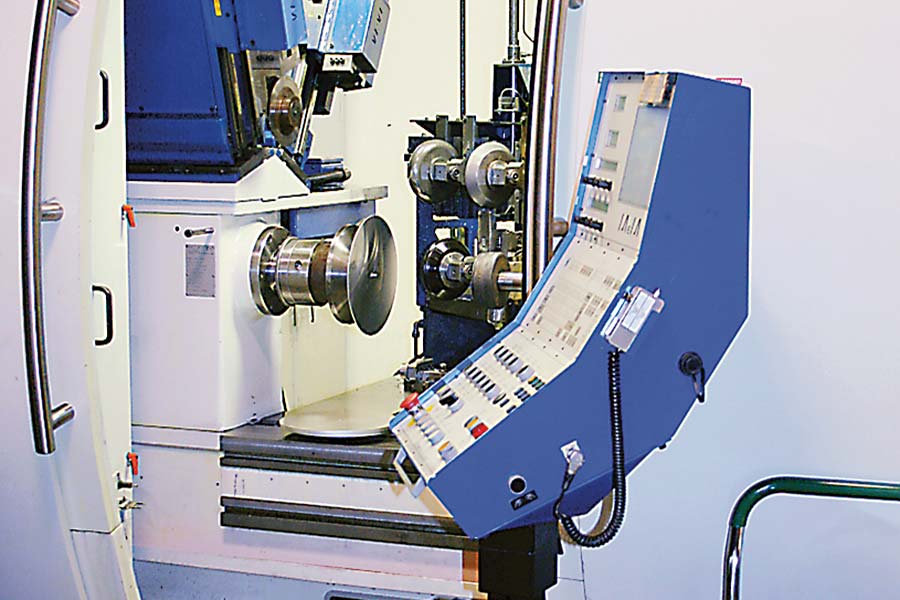

Our craftsmen still hand-spin daily while fully automated “force–controlled” CNC machines also produce precision spun shapes programmed by our engineers. This blend of technology, matched with our experienced personnel, has established us in this industry and remains center stage as one of our core competencies.